제품정보

The nozzle plays a vital role in the laser cutting process. Its primary function is to use high-pressure auxiliary gas to effectively remove impurities such as oxide layers and grease on the surface of the material, create favorable conditions for the penetration of the laser beam, and ensure the accuracy of cutting. The nozzle is usually made of high-temperature resistant and high-hardness materials such as quartz, ceramics or metals. The structure is stable and can withstand the high temperature and airflow impact during laser cutting. In terms of working principle, the laser beam is first collimated and focused to form a light spot with high energy density. Subsequently, the auxiliary gas in the nozzle is precisely guided to blow away the material around the light spot. At the same time, the material undergoes a process of heating, melting and vaporization under laser irradiation, thereby achieving precise cutting. In short, the nozzle significantly improves the quality of the cutting surface and the overall cutting efficiency through the synergy of precise gas control and laser beam.

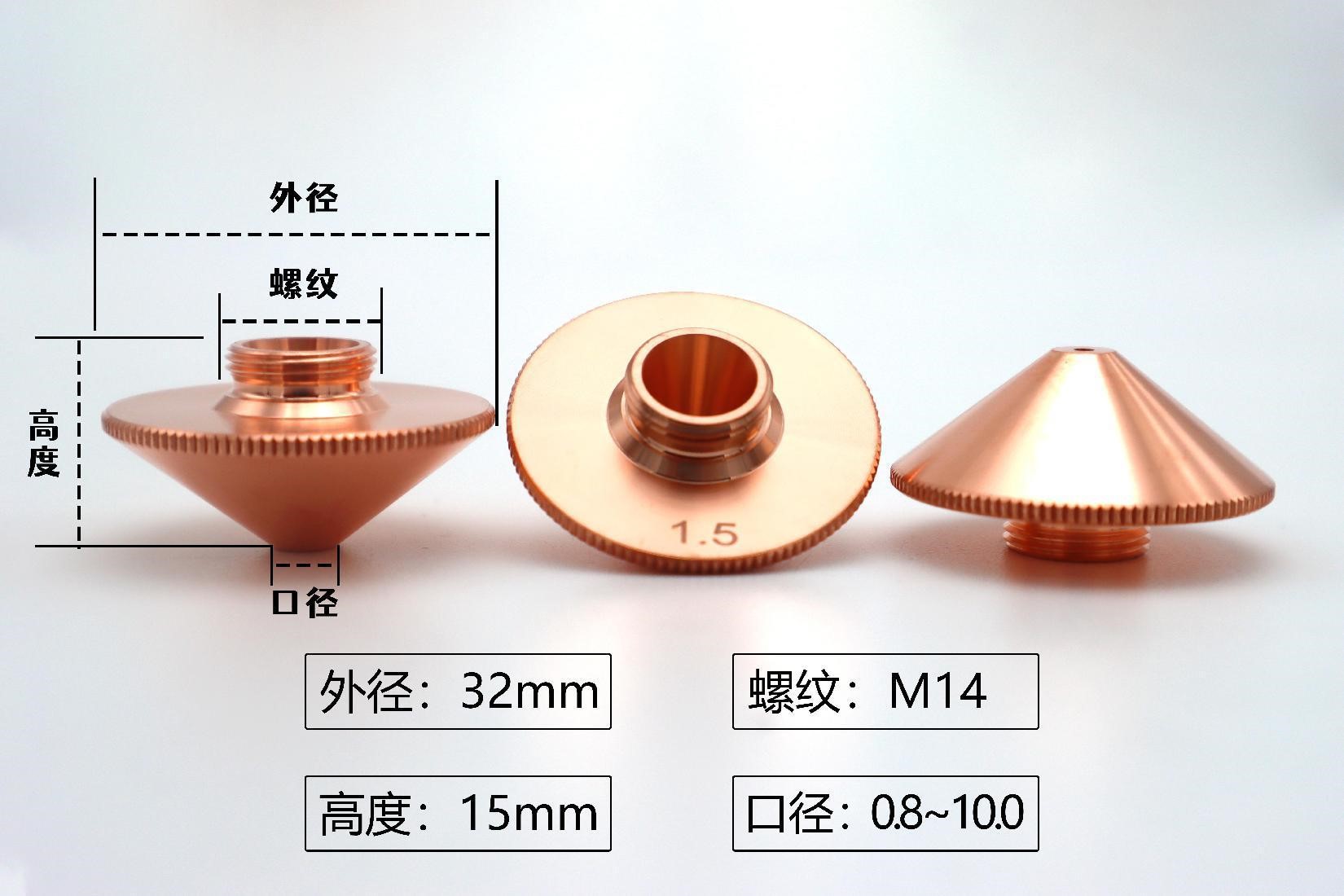

1번째 이미지

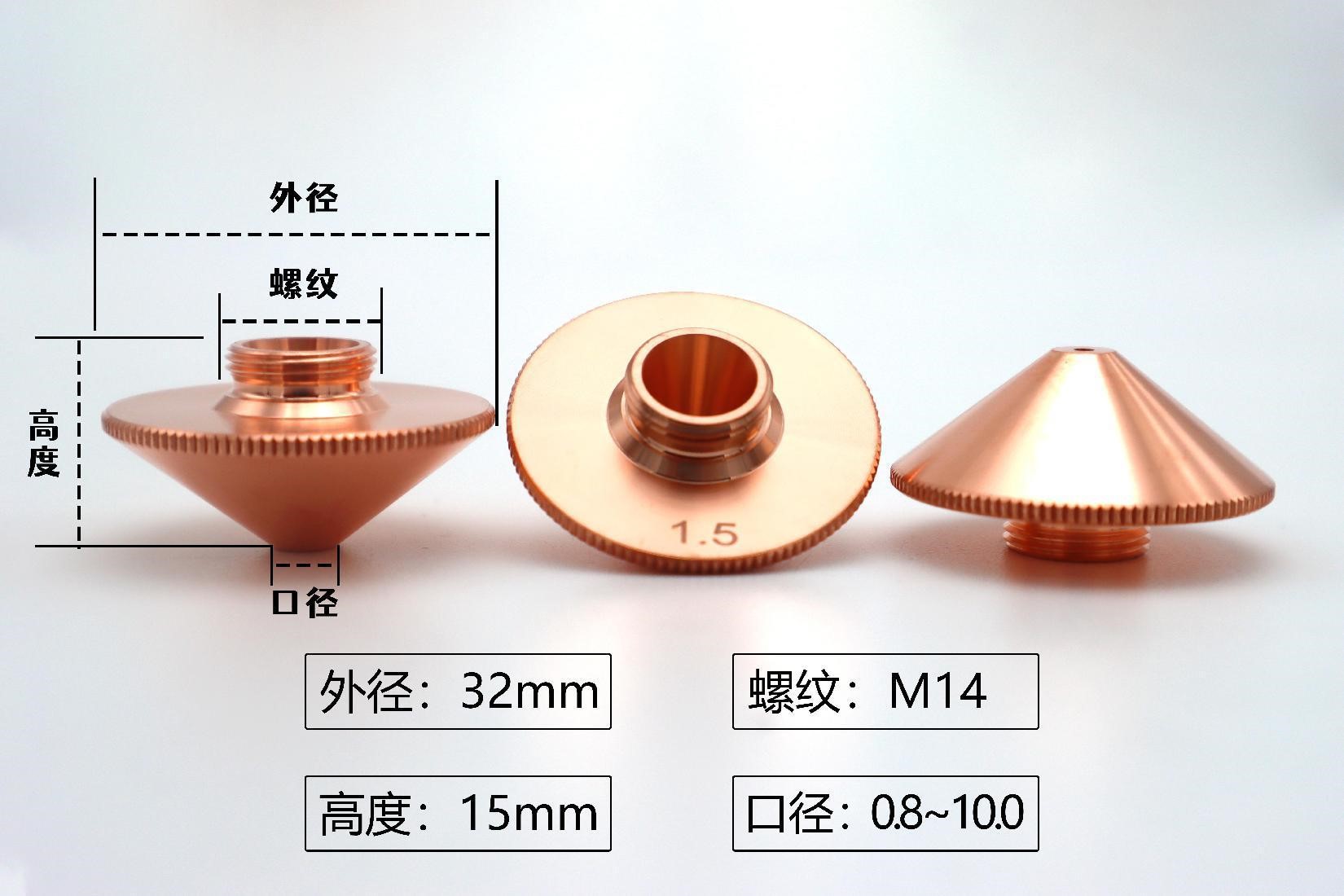

1번째 이미지